General Information

General Construction:

The Scamp trailer is built with a fiberglass body which is fastened onto a steel frame. On the standard trailers the interior cabinets are also made of fiberglass. Deluxe trailers have interior cabinets made out of wood. These interior cabinets do help support the body of the trailer, and they should not be removed for a long period without some support put in their place. The closet by the door or wood panel on deluxe trailers is especially important in supporting that side of the door opening.

Frame:

The frame is constructed on 3 inch by 1 1/2 inch 11 gauge pre-primed tubing. Cross members are welded angle irons. Formed steel is also welded on and the floor is screwed down to it. The frame is not designed to have a hitch installed on the back to pull boats or other trailers. It also is not designed to have a tool storage box or other heavy items attached to the rear. Any damage which occurs as a result of such use is not covered under the warranty.

Exterior Fiberglass:

Scamp trailers are built using an FRP open mold process. FRP stands for fiberglass reinforced resin. The exterior paint is called Gelcoat. It is a resin with pigment added. The Gelcoat bonds chemically to the FRP structure and becomes part of the supporting structure of the trailer. The pigments in the Gelcoat can be gradually broken down by sunlight. Over the course of time sun causes the Gelcoat to change, either yellowing to oxidizing. Waxing the trailer, covering it, or storing inside greatly reduces this process. Wax that works well on fiberglass products can be purchased at any boat dealer or many auto parts stores. If Gelcoat becomes chalky looking over time buff the chalkiness out using fine rubbing compound.

|

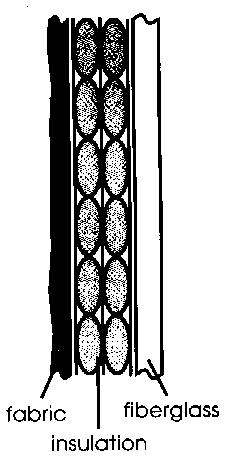

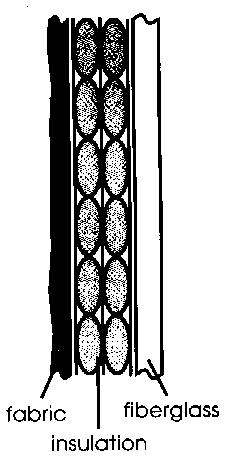

Insulation and wall headliner:

Double-bubble foil sided insulation is used. Insulation is glued onto the roof and walls of the trailer with a non-flammable adhesive. R value is about 15. The headliner is glued into the insulation using the same adhesive. The walls and headliner is a marine fabric which should be cleaned by using Woolite or upholstery cleaner.

|

Flooring:

The floor is constructed of OSB sheeting which is undercoated with fiberglass resin. The OSB sheeting soaks up the resin making the underside of the trailer extremely waterproof. The frame is caulked, then the sheeting is screwed down to the frame. Paint covers the floor in cabinet areas. Carpet is on the main floor.

Windows and Plexiglas:

The solid front and rear windows are Plexiglas. Sliding or crankout windows are standard RV windows. All windows should be closed while traveling, especially on gravel or dirt roads, which prevent dust from entering the trailer interior. All windows can be cleaned with water or window cleaner. If the Plexiglas gradually becomes scratched by road debris or improper cleaning, polish can be purchased to buff out the scratches. If a window pane is broken in a slider or crankout the window can be removed and the pane replaced. Procedure is as follows: 1. Square crankouts: Crank the window all the way out. Remove the two screws from each end. The entire frame then will come loose. 2) The radius-corner crankout and normal sliding windows: The procedure needs two people: one inside the trailer, one on the outside. Inside man with a drill with a number two square drive bit. Outside man keeps the window from falling as it becomes loose. The window is held in place by the interior lockring, which is fastened in place by square drive screws. As the screws are removed the lockring will come loose from the window allowing the window to be removed from the exterior of the trailer.

Hitches:

1) 13 foot trailers use an A frame 1 7/8 inch coupler with a 2000 pound rating. The coupler is adjustable by loosening or tightening the nut on the locking mechanism. A 1 7/8 inch ball is required for use with this coupler.

2) 16 foot trailers use an A frame 2 inch coupler with a 5000 pound rating. This coupler is also adjustable with a nut on the locking mechanism. 2 inch balls are required with this coupler.

3) Fifth wheel trailers use a gooseneck type of hitch also with a 5000 pound 2 inch coupler. This Atwood coupler is not adjustable, but locks in place with its own system.

4) Fifth Wheel Truck side Hitch: The vehicle hitch consists of two L shaped brackets bolted through the bed of the truck and sidewalls of the wheel wells with 3/8 inch bolts. The cross member is constructed of 3 inch ship and car channel, bolted on with 4 1/2 by 1/2 inch bolts. This hitch also uses a 2 inch ball. Sometimes the trailer is too far forward or rearward for the hitch to release correctly. If so, move the vehicle slightly to release the hitch. Do not raise the tow vehicle with the trailer landing gear (jacks) as damage may result.

Jacks and Landing Gears:

1) Front swivel jack, used on 13 foot trailers (and 16 foot trailers before 1994). 1000 pound rating. To operate, pull out the spring loaded locking bracket, jack will release and snap downward manually, and lock in place. Care should be taken not to jackknife the trailer damaging the jack and the bumper of the tow vehicle.

2) Front center mount jack, used on 16 foot trailers. 2000 pound rating. Mounts in the center of the 5000 2 inch coupler. To use turn crank clockwise to go up, counterclockwise to go down. Since this jack protrudes lower than normal often a raised ball or a receiver hitch with a raise is needed to keep the jack from dragging over curbs or uneven ground.

3) Landing gears used on fifth wheel models. 4000 pound capacity. It is not necessary to extend all the way up or down by cranking. When unhitching from the vehicle remove the extension pins and let the legs down to the ground (level ground should be chosen). Put the pins back in, locking the legs in place. Extend legs further by cranking the remaining distance. To extend the legs crank counter-clockwise, to retract crank clockwise. Do not force gear end when end of leg extension is reached as this can damage the gears. Make sure that all pins on the landing gears are in place before travel, otherwise landing gear legs or landing gear feet may be damaged while towing.

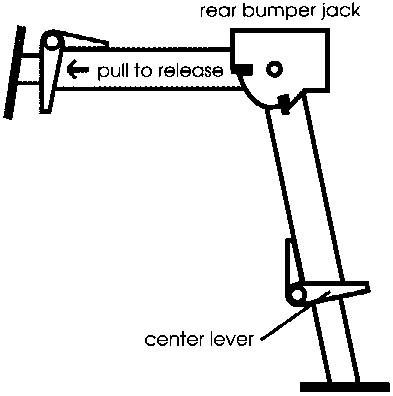

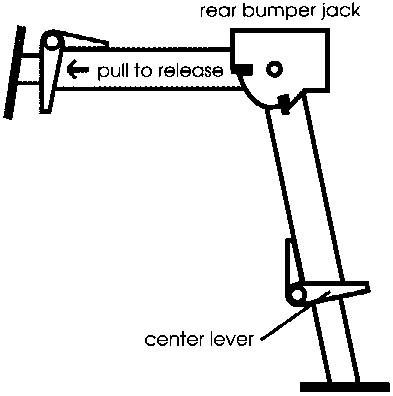

|

4) Rear bumper jacks: 1000 pound capacity per jack. Mounted with two 3/8 by 1 inch hex head bolts. This jack is spring loaded. Use requires pulling the jack toward the center of the trailer which releases the spring. The jack manually swings down and locks into place at about a 15 degree off vertical. Push center lever down to release leg which will drop down to full or necessary length. Insert 1/2 inch zinc coated rod through desired front hole of jack. Pushing down on rod will force the jack down further. Total drop fully extended on 13 foot trailers is 17 3/4 inches. On 16 foot trailers the drop is 21 3/4 inches. Do not over extend. Also, soft soil requires wood blocks under jacks for good stabilization.

WARNING: DO NOT USE STABILIZING JACKS FOR TIRE CHANGING!

|

Click for next section -

Appliances